It has been researched that almost $500 billion of goods are damaged due to container moisture. It is a fact that containers always contain moisture, and their floor is always damp. Moisture can occur due to the pallets left outside in the rain. Temperature fluctuations are also a big reason for causing moisture and condensation during transport. This moisture can bring in mold, rust, odour and collapse products. Therefore, desiccants are advisable to use in this situation because they capture excess moisture and reduce the chance of damage.

Controlling moisture plays an important role in keeping the products dry during transportation. You might know that the delivery or storage involves areas with high humidity and can result in damaging the goods and increase expenses along the way. The temperature change that takes place during transportation can lead to moisture.

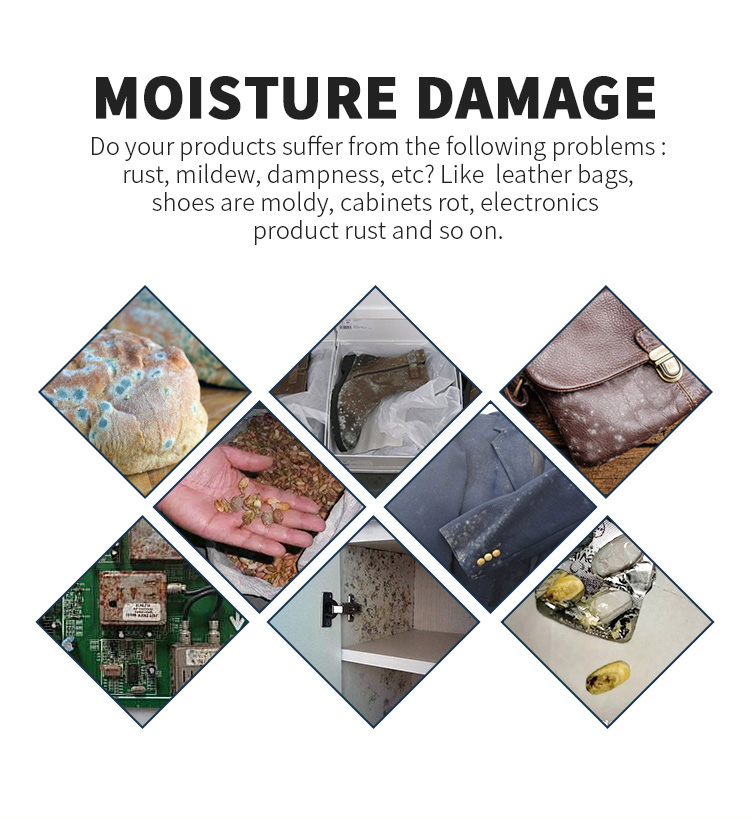

Below are some of the damages caused due to moisture:

- Corrosion: When exposed to moisture, the equipment or products made of iron can lead to rusting. Rusting can’t be easily removed, and if we do so can lead to further damage.

- Musty smell: The growth of mold, fungus or bacteria due to the increased moisture level can cause a funky smell on some products. Getting rid of this smell caused by moisture takes work, especially for products like books and clothes.

- Dampening: The major damage caused due to moisture is the dampening of items, especially those products which are highly absorbent of moisture like paper and garments.

Solutions for Moiture Proof

Desiccants in cargo:

When goods are transported by sea, the containers are majorly exposed to risks like temperature and moisture, and many goods are wasted.

Here the desiccant bags are utilized in the cargo and other shipping containers. The bags have been specially developed for controlling moisture effects in containers. They prevent corrosion, clumping of powdered products, dampness, mold and fungus.

1.Desiccants in boxes: Silica Gel Desiccant Packets,Calcium Chloride Desiccant,Clay Desiccant Bags,etc

Desiccants can be used in various product packaging like shoes, clothing, electronics and pharmaceutical products. These products tend to get easily affected by moisture; for this purpose, the desiccants are made to absorb the excess moisture and result in moisture-free delivery.

2.Container Desiccants:1kg container dry pole,1kg container dry strip,1400g container dry strip,2000g container dry bags

Here we have various solutions for controlling moisture damage:

- Installing a climate control storage unit: Now, some transport units have climate control units that help to manage the temperature and humidity in a particular area. With this, moisture damage can be prevented to an extent. The units are quite expensive.

- Stretch wrap and pallet covers: Using pallets during transportation makes delivery and shipping much easier. These are quite useful for products to protect them from rain. So, use the pallet covers, pallet shrink films and stretch wrap.

- Protect the wood with timber wraps: The timber wraps are waterproof and durable for storing and transporting wood. The woods are wrapped with timber for better protection from water and moisture.

- Use dry and sturdy corrugated cardboards: Some might think cardboards absorb moisture easily, but corrugated cardboards very easily wrap with moisture. They even keep dampness out of the products. When wrapped with stretch or pallet shrink films, products provide complete moisture protection.

Other than the above solutions, some desiccants keep the environment dry and moisture-free.For example,silica gel desiccants are hygroscopic substances that help them to absorb enough moisture from goods and products. Most packaging and shipping companies utilize these desiccants to remove moisture from goods and products during transportation.